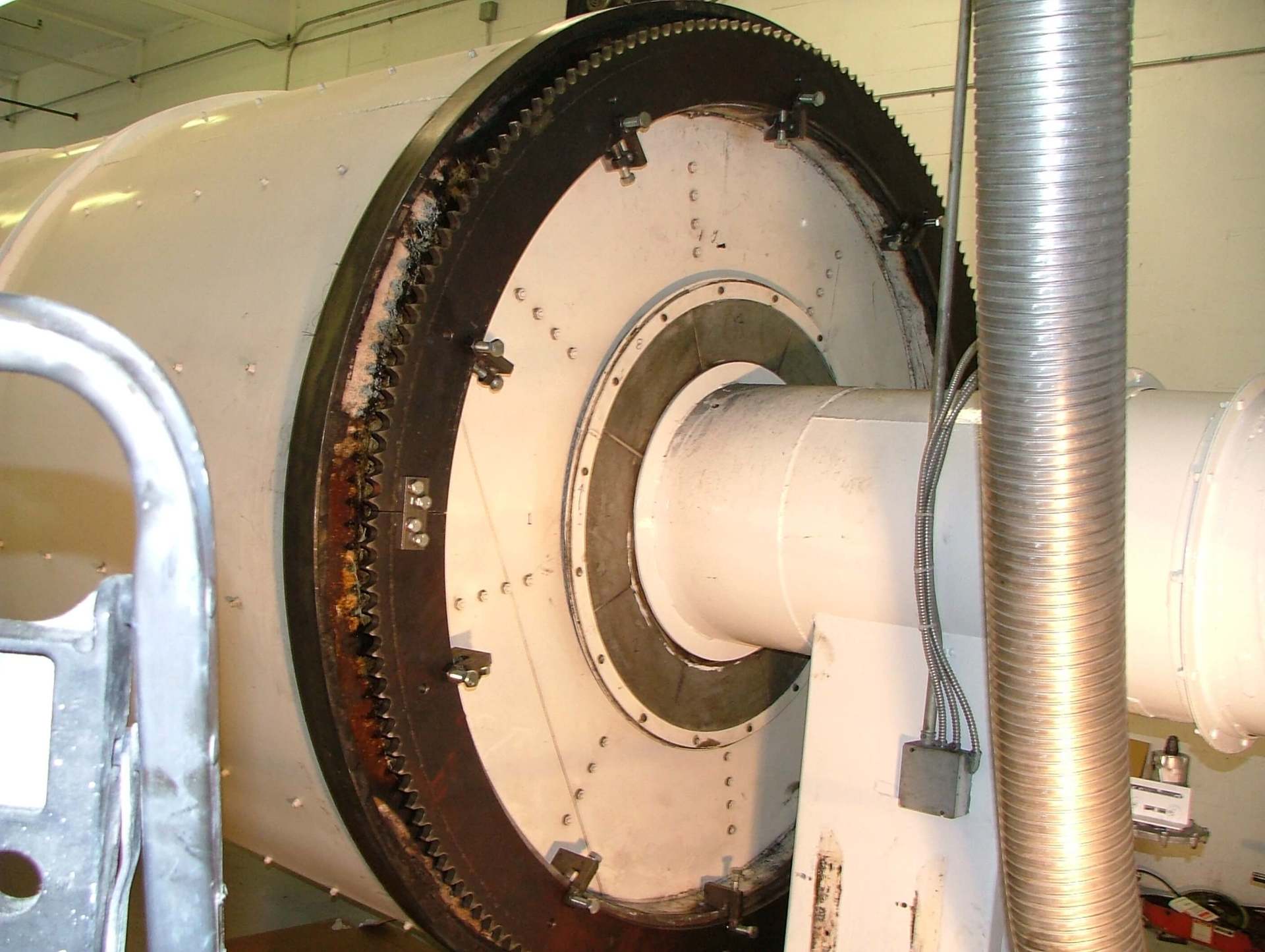

DRIVE ASSEMBLY

CHAIN & SPROCKETS / GEAR & PINION / FRICTION DRIVE /DIRECT DRIVE

The drive assembly is the mechanism that causes the drum to rotate. Several options are available here:

- chain and sprocket

- gear and pinion

- friction drive

- direct drive setup.

A chain and sprocket setup are ideal for smaller rotary drums, running up to 75 horsepower. Gear and pinion drive assemblies are reserved for more heavy-duty applications, running above 75 horsepower. A reducer decreases the speed of the motor for higher torque applications with both drive assembly types. Friction drive assemblies are used for very small drums with low horsepower, typically drums around 6’ and under. In this setup, two of the four trunnion wheels are connected by one shaft and driven by a shaft mounted reducer and motor arrangement. The direct drive setup is used for small to medium size drums with motor sizes up to 75 horsepower. The design consists of a shaft mounted to a solid, discharge end plate at the outlet of the dryer. The motor and reducer are either directly connected to this shaft with a coupling, or a shaft mount arrangement.

SYMPTOMS OF DRIVE ASSEMBLY ISSUES INCLUDE:

- Kilin vibration

- Knocking & pounding in the main gear & gear reducer

- Main gear & pinion not maintaining proper mesh

- Scoring of gear teeth & peeing of pinon teeth